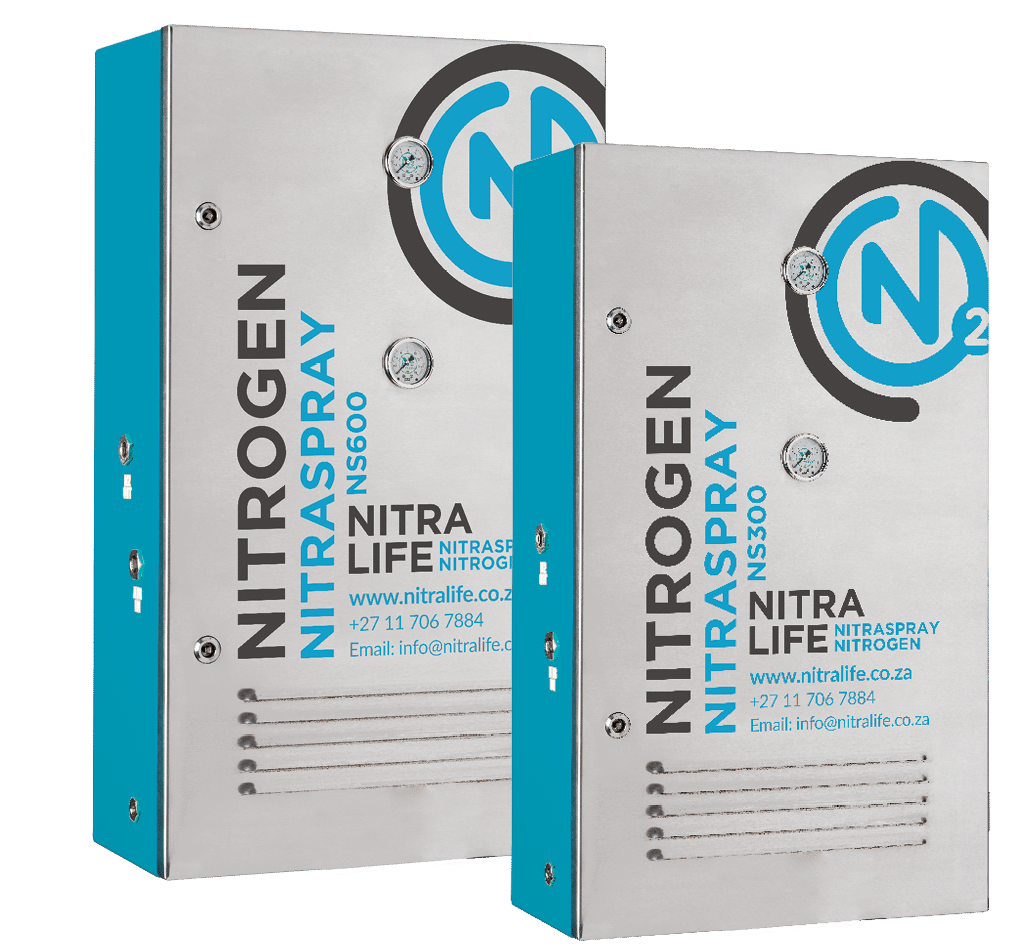

Nitraspray Nitrogen solutions for

spray painting applications

Do you require a custom nitrogen solution?

Our Nitrogen solutions can be customised and manufactured to your specific needs.

Call us today to see how we can partner with you.

Nitrogen in spray painting applications

The use of nitrogen as a paint carrier is specified for professional spray painting and offers overall quality improvement and savings in paint consumption. Nitrogen gas is pure, clean and dry, helping reduce over-spray. Factors such as fish-eyes, pin holes and orange peel are a major cause of rework, extra cost and lost time. With the use of Nitraspray nitrogen, a spray painter can significantly improve productivity and quality as well as decrease paint costs by 10 – 15%.

Nitrogen in other industries

The use of nitrogen has benefits that extend across a wide variety of applications and industries. A primary target market for on-site nitrogen generation has always been high volume/constant-use industrial applications like plasma and laser cutting; and also in tyre inflation market for large open cast mining, long-haul transport and the passenger tyre market. As a pure, clean, inert gas – Nitrogen contains no oxygen and therefore it does not oxidise or retain heat, and when used in tyres it means they will not over-heat making them safer and better performing. The use of on-site nitrogen for laser cutting provides the customer with an affordable, dependable method to produce their own nitrogen assist gas on-site, 24 hours a day, and for a fraction of the normal cost.